Letter from the President

Watch: Signal Hill Chamber of Commerce Welcomes M4 to the Community

On August 12, 2020 the Signal Hill Chamber of Commerce held a ribbon cutting to celebrate the establishment of M4’s new Testing and Prototyping Center. As the only new Signal Hill business to hold a ribbon cutting during the COVID-19 pandemic, us at M4 are incredibly grateful for the opportunity to expand out capabilities and become a part of such a great community.

M4’s Internship Program Promises a Rigorous and Hands-On Experience

Every year, M4 hires new recruits to their Internship Program for young engineers looking for a real-world experience. Whether it’s through research or making hand calculations, each intern has the opportunity to learn what it’s like to work at an engineering company, beyond the theories they’ve learned in school.

Tyler Winter, who hires M4’s interns, thinks good communication and confidence are key indicators of a good candidate for M4’s Internship Program. However, what Winter truly thinks makes an intern special is if they can answer a quiz problem that engages critical thinking. Winter believes it communicates whether a person might be a good fit for a small company like M4 and especially speaks to their communication skills.

Robert Nguyen, Daniel Tran, and Brent Scheneman were all successful interns at M4 and were eventually hired full-time.

Nguyen, a new M4 engineer, said the program is rather rigorous, but appreciated the different types of projects he was able to work on. Though he felt he was “thrown into the deep end,” he ultimately benefited from his internship and learned more than he originally expected.

Tran mostly appreciated the people he worked with and thought the internship was best for learning from his co-workers. He also learned the value of programming. Tran especially thinks his internship led him to become more efficient and insightful in his analyses.

Scheneman loved working with his hands and even had a trip to Palm Springs for his first major project on a wind turbine. Though Scheneman left the company for a few years, he recently returned and actually became M4’s Manufacturing and Test Manager. It meant he has more responsibilities, but he still sees the benefits of his internship at M4.

Internships can be beneficial for anyone looking to gain real-world experience, even for M4 Vice President Dr. Kevin Roughen, who learned of the value of an internship when he was an intern in 1997. While he recognizes the value of schooling, he believes internships are most valuable for learning how to apply theory to real-life problems. He especially benefited from learning the skill to define any problems he faces in his day-to-day work.

Dr. Roughen also mentioned how the relationships you make during your internship can be beneficial for your future career. In fact, Dr. Roughen met M4 CEO Dr. Myles Baker through his McDonnell Douglas/Boeing internship, and the pair have worked together for twenty years. Roughen emphasized the worth of meeting people during the internship, especially when it comes to teamwork.

All-in-all, internships are a great way to meet new people while also gaining practical skills that some students miss out on when learning only theory and programming. M4’s internship can prove to be beneficial for all aspiring engineers who are looking for a hands-on experience that’s rigorous but still unique, engaging, and full of a team of engineers who are willing to help.

Aerospace Engineering Intern

We are currently seeking a highly organized, enthusiastic individual to join our engineering team. The successful candidate will have the opportunity to work with a dynamic team performing engineering research and analysis for Department of Defense, NASA, and commercial clients. Internship opportunities are available in the areas of:

- Structural Analysis

- Multidisciplinary Design Analysis and Optimization (MDAO)

- Engineering software development

Aerodynamics/CFD Analysis Engineer

An aerodynamic analysis engineer is needed to perform aerodynamic analysis of various configurations. This individual will have primary responsibility for computational fluid dynamics analysis tasks from grid generation through post-processing and interpretation of results. The candidate will present analysis results to both internal and external customers.

Lead Aerospace Design Engineer

The lead designer will be responsible and maintain ownership for the overall design components and/or systems based on a set of requirements and constraints, and oversee the project from concept to production. Some common tasks include:

- Driving design solutions and leading a design team to deliver a solution that meets requirements

- Designing mechanical / structural systems and products based on set given and derived requirements

- Perform related analysis (simple FEA) and classical hand calculations to optimize design of product

Manufacturing and Test Technician

A manufacturing and test technician is needed to support M4’s growing manufacturing and test capability. This individual will have primary responsibility for supporting a wide range of aerospace programs. Responsibilities may vary from executing test procedures, designing and fabricating test fixtures, composite part manufacturing, and general shop equipment maintenance.

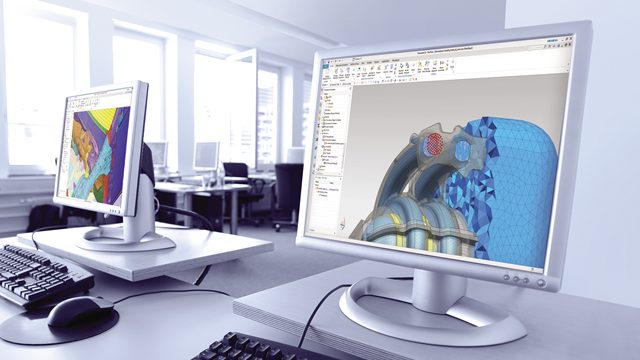

Product Spotlight: Siemens Simcenter 3D

In a world where product complexity is constantly increasing, electro mechanical systems with embedded software are becoming the norm, and global competition is on the rise companies are always looking for an edge that will allow them to get to market faster with better products. As a result, there are many software providers and tools trying to fill that gap with various point solutions that address certain challenges, without necessarily addressing the overall process. Siemens Digital Industries Software (DISW) is addressing the whole product development, manufacturing and real world usage through its Xcelerator platform. Xcelerator brings together and integrates the entire Siemens Digital Industries Software portfolio with embedded tools and databases connecting current and future information technology, operational technology, and engineering technology environments. In today’s Product Spotlight we will discuss Simcenter 3D, which part of the Siemens DISW Simcenter Simulation and Test Portfolio.

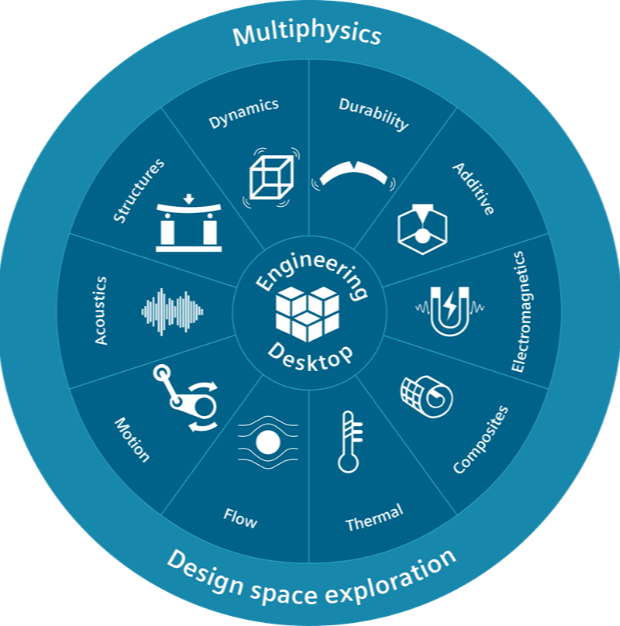

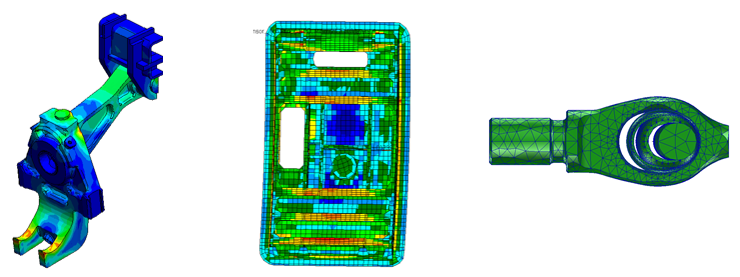

Simcenter 3D delivers a unified, scalable, open, and extensible environment for 3D CAE with connections to design, 1D simulation, test, and data management. Simcenter 3D speeds up the simulation process by combining best-in-class geometry editing, associative simulation modeling, and multi-discipline solutions embedded with industry expertise. Fast and accurate solvers power structural, acoustics, flow, thermal, motion, and composites analyses, as well as optimization and multi-physics simulation.

Simcenter 3D is the ideal tool for the general simulation analyst team. Simcenter 3D not only delivers the meshing and simulation capabilities an analyst needs, but also delivers sophisticated tools for working with geometry from any CAD system. Simcenter 3D allows simulation teams, comprised of structural, thermal, flow, and motion analysts, to operate in a single environment instead of working in multiple disparate simulation tool environments. This can help commonize processes within the team as well as help keep data more closely linked together between simulation domains.

Simcenter 3D can be used as the primary pre- and postprocessor for Siemens PLM Solvers, Simcenter Nastran and Simcenter Samcef, or for a number of third-party solvers, such as Abaqus, ANSYS, LS-DYNA, and MSC Nastran. This is accomplished through immersive user environments that use the selected solver’s terminology, which enables analysts to easily prepare solver-specific analysis models without the need to learn new terminology. This helps simplify the user experience.

In summary, Simcenter 3D stands on four key capabilities that deliver:

· A faster CAE process achieved through an integrated user environment, which offers best-in-class geometry editing tools.

· Multidiscipline integration to predict real-world performance for a large variety of physics domains.

· An open environment that supports common third-party solvers and scales to meet the needs of simulation user skill sets.

· Direct connections to the digital thread through the greater Simcenter portfolio.

To learn more about Simcenter 3D, Simcenter Portfolio or Xcelartor please reach out to us at https://m4.kaydiandesign.com/contact/ or give us a call at (562) 981-7797

The Long Beach Accelerator™ provides early stage startups with the support, resources and funds they need to flourish.

Inaugural cohort kicking off in January 2021. Click below to find out more info and apply.

In the Works: Recently Won Proposals

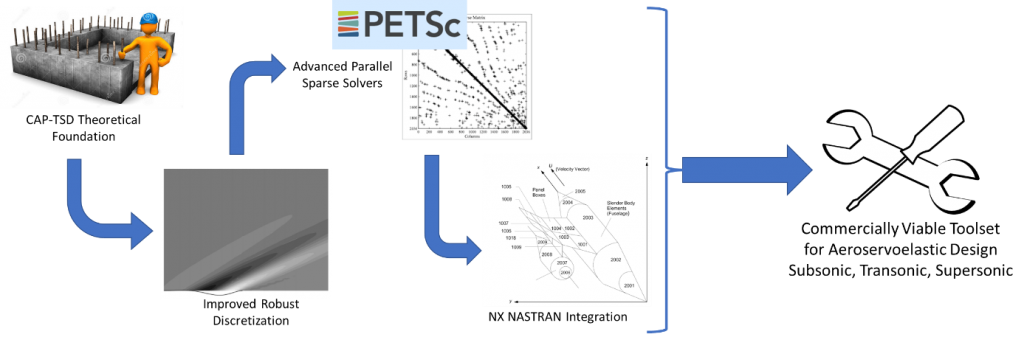

Innovative Aerodynamic Modeling for Aeroservoelastic Analysis and Design

Predicting the behavior of aircraft flying around Mach 1 is difficult, because the character of the aerodynamics changes when going from subsonic to supersonic and back. When the aircraft is flying near Mach 1, some regions of the flow will be subsonic, and some regions will be supersonic. As the aircraft moves, these regions shift around, changing the forces on the vehicle. This change in forces affects the vehicle motion, creating an aeroelastic feedback loop that can result in unpleasant “surprises”. M4 has been selected to implement a capability for transonic aerodynamics, especially tailored to the aeroelastic and aeroservoelastic analysis, optimization, and control of aircraft around Mach 1. The project combines technologies from unsteady aerodynamics, automatic mesh generation, and optimized numerical algorithms to provide an easy path to transonic aeroservoelastic analysis that can be integrated into industry-standard processes without requiring every analyst to be an expert in aeroservoelasticity as well as CFD.

PI: Dr. Myles L. Baker

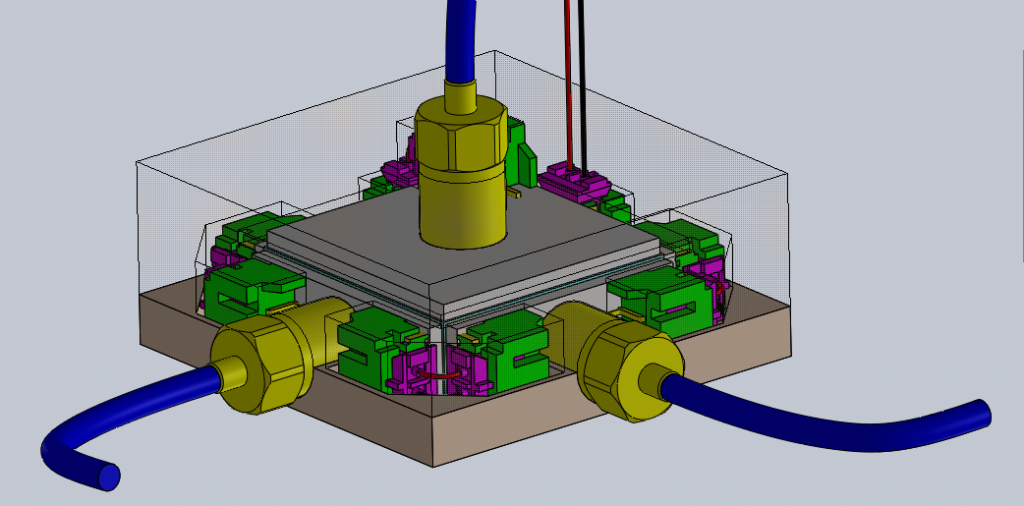

Cryogenic Vibration Testing

Testing at cryogenic temperatures is required for many space missions, but it has many challenges that are not obvious at first glance. For example, shock and vibration testing requires measuring the shock and vibration using accelerometers, but many accelerometer technologies break down at liquid nitrogen temperatures. And when your instrumentation drops out, your testing shuts down. This project focuses on ways to improve accelerometer performance at cryogenic temperatures to improve reliability and throughput of cryogenic dynamic testing.

PI: Dr. Myles L. Baker

SubFEM2 Navy SBIR Phase II

The finite element method has been well-established for modern structural design and analysis. However, significant modeling choices must still be made in trying to achieve accurate answers efficiently, especially for high value complex structures such as submarine hulls. M4 Engineering is working with the U.S. Navy to create comprehensive guidelines to standardize submarine hull structure modeling best practices, as well complementary AI software tools to provide automated modeling recommendations for specific submarine designs to protect our sailors and enable successful missions. The design recommendations and the process for developing them will be validated via a companion experimental program that will be planned fully during Phase II for execution during Phase III.

PI: Dr. Daniel Hammerand

Employee Spotlight: Vitaliy Rezekulov

As a new quarter begins, we would like to recognize Vitaliy Rezekulov, one of our outstanding engineers who recently celebrated his seventh year at M4! Vitaliy is a Senior Engineer in the Engineering Services department, where his main responsibilities include structural/stress analysis and leading teams to help solve partners’ complex engineering challenges. Vitaliy is also responsible for managing our Technical Sales team, which helps connect companies to Design, Simulation and Optimization software solutions. In this role he has been an integral part of starting and growing the M4 engineering software business.

Originally from the historic city of Lviv, Ukraine, Vitaliy attended the University of Minnesota for Mechanical engineering. Vitaliy was drawn to Mechanical engineering because of the broadness of the field, as he enjoys learning about the many different domains of engineering. This love of learning extends to his position at M4, where he excels in his ability to work on many different types of projects, each of which carry unique engineering challenges. Some of his favorite contributions have included working on injectors for rocket engines, developing intricate Python programs, and collaborating with his peers to identify creative solutions for complex problems.

Vitaliy commented, “One of my favorite assignments at M4 was leading a team of engineers at a launch vehicle startup company. It was exciting to see and hold real-life rocket components, knowing that it is possible these components may one day travel to space.”

Not only does Vitaliy shine in the workplace, he also doubles as a loving foster parent to an 11 month old baby boy! He reflected, “Becoming a foster parent has been a rollercoaster ride, but my wife and I wouldn’t trade it for anything. Seeing all that a tiny human can learn in just under a year is mind blowing!”

When he is not spending quality time with his family or working tirelessly on hydraulic actuators and cryogenic vent relief valves, Vitaliy enjoys playing sports (namely soccer and hockey), listening to Coldplay, watching movies such as Schindler’s List, and sitting down with a good book. With such a strong work ethic and incredible ability to multitask, we wouldn’t be surprised if he does all four at once!

Vitaliy, we greatly appreciate all the contributions you have made to both M4 Engineering and the community. From everyone at M4, thank you!

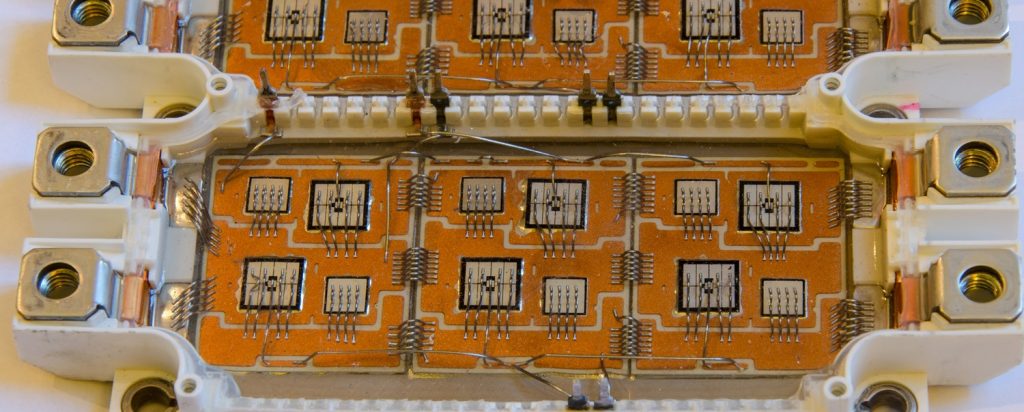

Testing of High-Power IGBT, Power Transistor, Power Diode, and MOSFET Semiconductor Devices

There’s an art to semiconductor development and testing thanks to the competing constraints imposed by time, money, precision, repeatability, and test coverage. Teams that are able to leverage accelerated lifetime testing and failure diagnosis gain a valuable advantage over their more traditional competitors.

Dynamic Stability Derivatives Using CFD

While it is relatively simple and commonplace to leverage CFD to determine static stability characteristics of an aircraft such as CLα and CMα , it is more challenging to determine dynamic stability characteristics. Here we will demonstrate how CFD can be used to estimate the pitch damping derivative (Cmq of an aircraft. For this study, we will be analyzing the eFlyer 2 which is an all-electric aircraft being developed by Bye Aerospace.

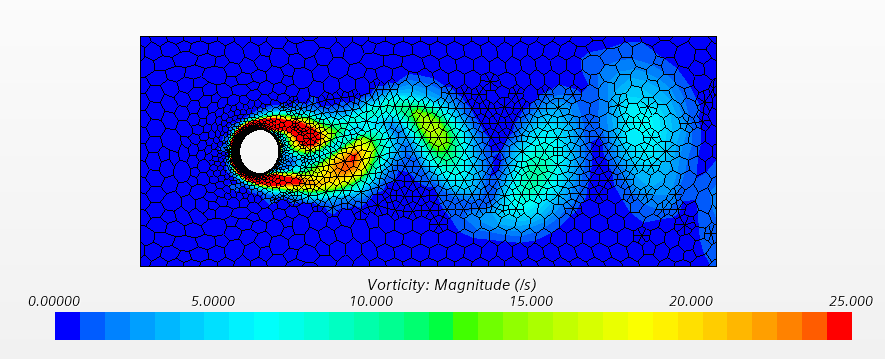

Simcenter Star-CCM+ Adaptive Mesh Refinement Case Study: Cylinder in Crossflow

You can reduce simulation time by using Adaptive Mesh Refinement. Adaptive Mesh Refinement (AMR) is a dynamic meshing technique that can coarsen or refine elements based on user-defined criteria computed during the simulation. This functionality enables the analyst to run more simulations faster and drastically reduce simulation time.

The Vertical Flight Society invites student teams to participate in the inaugural VFS Design-Build-Vertical Flight (DBVF) Student Competition. This electric-powered remote-control vertical take-off and landing (VTOL) competition seeks to encourage interest in unmanned aircraft technology, and small air vehicle design and fabrication. The competition is designed to develop hands-on skills and familiarization with eVTOL and Urban Air Mobility (UAM) technology at the university student level and prepare the next generation of engineers and leaders to push the limits of this exciting technology into the future.

The fly-off portion of the competition is scheduled to take place at the U.S. Army Combat Capabilities Development Command (CCDC) Army Research Laboratory (ARL) Robotics Research Collaboration Campus (R2C2) at Graces Quarters in Maryland on April 16-17, 2021. Download the APG Visitors Guide for more information, which includes directions and visitor access information.

The general aircraft requirements are restricted to the unmanned aircraft system (UAS) Group 1, which limits the maximum take-off weight (MTOW) to no more than 20 lb (9.1 kg). Aircraft size and weight will factor into the competition scoring as described in the scoring section of the Request for Proposal.

Proposal submission date extended to Oct. 15, 2020 – send to fly@vtol.org.

M4 Community and Academic Outreach: CANStruction

We strive to be a good citizen and neighbor and give back through local veteran, humanitarian youth/educational, economic and business organizations near our offices. And even with all our good intentions, sometimes it is harder than it should be. Especially these days. It feels like learning to walk again. All the progress, meetings and efforts we have made over the past three years to reach out to our local and academic community have slowed down and eventually come to a halt. We went from a slow crawl to a light jog, and then boom. COVID 19.

Our community outreach journey started with a request to support the VEX Robotics team at CAMS (California Academy of Mathematics and Science). One of their members reached out to our president for a donation:

“Our club is encountering many problems due to our lack of funding. We really need your help. We’ve fundraised some money this year, but only enough to register us for competitions. Most of these competitions are very far away; we normally stay in a hotel the night before and work on the robot until the morning of the competition. This was how my national-level robot was built. But this year, we have no money to afford even a bus for transportation”. Our President passed this on to me saying he would donate something, but maybe there is more we can do with CAMS. And we did, but I will save that story for another time.

We are currently working with LBUSD to see if we can support an engineering centric webinar series for interested students, how we might be able to offer High School Internships and Teacher Externships. And maybe, right now this looks like a pretty big maybe get more schools involved with LB CANstruction in Spring 2021.

We are also reaching out to CSULB to see how we might be able to work together and support their various STEM related clubs and activities. It is strange how doing good is harder than expected, but then again everything these days, seems harder and stranger.

So as I said, we are restarting our journey and learning to walk again. Let us know if you have any feedback, ideas, or want to help getting this effort restarted. We want to make 2021 a banner year in this area.

Through this first step we connected with Long Beach CaLL (Career Linked Learning), had students from Santa Ana shadow our engineers at M4, judged regional Robotics competitions, donated parts to Cal State Long Beach’s “Beach Launch Rocketry Team, supported Sato Academy’s RC Drone and Rocketry club and designed and built an award winning (People’s Choice Award) Dr. Seuss themed rocket ship in October 2019 at Canstruction Long Beach. This was done in collaboration with Sato’s students who raised over 600-cans and an additional cans that were donated that we used and were later gave to Foodfinder for distribution to nonprofit pantries and shelters throughout the region. We were on a roll.

2020 was going to be even better, but that’s not what happened. In March students were sent home, Canstruction got delayed then cancelled for 2020 and all the momentum came to a halt. No more clubs to support, no more industry banquets to attend at CSULB, and no more building on previous experience. M4 Academic & Community outreach 1.0 ended. Our nascent 2.0 outreach model requires a new mindset and approach.

Just for Fun!

Stay Connected!

Follow M4 on social media to always be in the know!